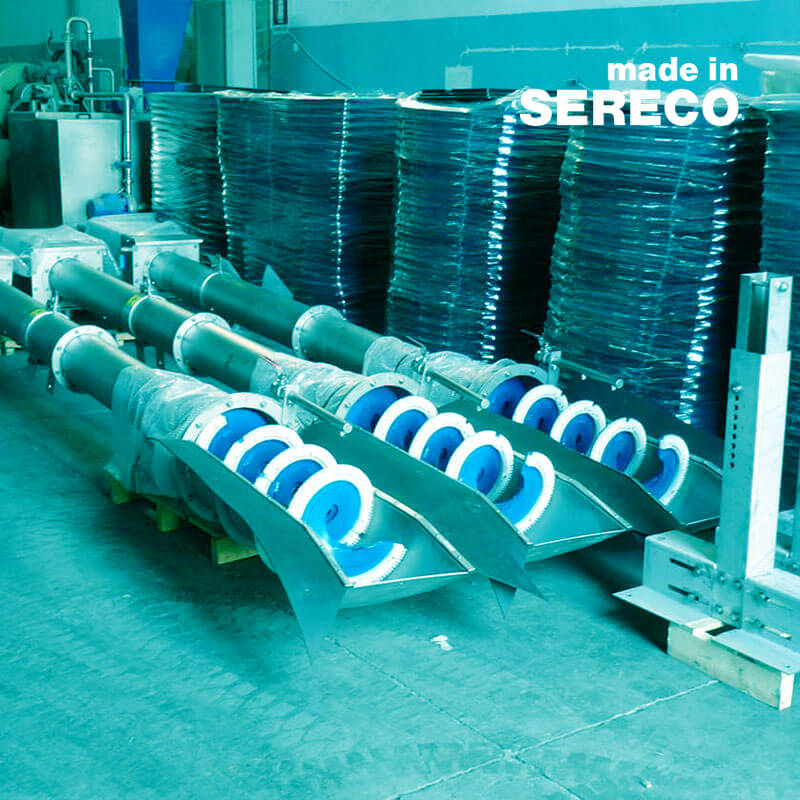

Shaftless screw filter

FCS

CATEGORY SEWAGE

TYPOLOGY SCREENS

WHEN TO USE IT

The screw filter is suitable for many applications, in particular it is suitable for the micro-screening treatment of wastewater of civil and/or industrial origin in treatment plants and for the filtration of sludge and supernatants. The FCS screw filter is used when a simple, cheap and easy-to-maintain machine is required.

HOW IT IS MADE

The main components of the FCS type screw filter are a multifunctional screw and a semi-cylindrical filtering screen. The standard filtering screen is composed of a semi-cylinder in perforated sheet where the filtering opening is determined by the diameter of the chosen hole. The shaftless multifunction screw is keyed onto a sturdy gearmotor and the various functions it must perform are ensured by two different diameters, one for screening and one for the other functions. The screw, in the first lower area, has a diameter proportional to the flow rate to be treated and therefore to the channel in which it must be installed. In the second zone, above the first, the screw has a smaller diameter and pitch, suitable for transporting and dewatering the screened material.

HOW IT WORKS

In the standard version, the screw filter is installed in a concrete channel where the water to be filtered flows, passing through the screen which blocks all solids with a diameter equal to or larger than the predetermined filtration opening. When the material accumulated on the screen creates a difference in water level between the upstream and downstream of the filter, a differential level sensor start to rotate the shaft of the multifunction screw. The lower area of the screw has a diameter similar to the diameter of the filtering screen so that through a brush mounted on the external profile of the screw it continuously and effectively cleans the screen. The second area of the screw, of smaller diameter, carries the screened material upwards, draining the water. After drainage, the third compaction area begins, where the screw, in order to perform the compaction function, always takes an increasingly smaller pitch upwards. Before being discharged and bagged into a suitable container, the screened material undergoes compaction and drying equal to about 50% by weight. The particular feature of this machine, with its completely closed body, prevents the spread of bad odors. The FCS screw filter is equipped as standard with a washing system for the filtering screen and the screened material with nozzles and pressurized water.

STRENGTHS

LARGE SPECIFIC FLOW RATES

COMPLETELY CLOSED MACHINE OUT OF THE CHANNEL ABLE TO PREVENT THE DIFFUSION OF UNPLEASANT ODORS

REDUCED MAINTENANCE DUE TO THE ABSENCE OF MECHANICAL PARTS MOVING IN THE WATER